New advancements in aluminium air batteries could see Tesla's new 'state of the art' lithium ion plant lose its innovative edge even before it opens. The USD 5 Billion facility, projected to open in 2017, was built to accommodate the production of up to 500,000 lithium ion batteries annually – batteries that are used to power the famous car brands' emission free vehicles.

However, unfortunately for Tesla, a company called Fuji Pigment Co. Ltd, announced in January it had a made a breakthrough in the use of aluminium air batteries – which could in theory have a capacity more than 40 times greater than the lithium ion cells being produced by Tesla. Fuji has stated that it will start commercializing its new product by the end of 2015 – a full two years before Teslas' own production line gets under way.

New Aluminium air batteries could radically transform the energy industry

Groundbreaking developments in the use of aluminium air batteries risk leaving the competition in the dust

December 3, 2015

Groundbreaking developments in the use of aluminium air batteries could radically transform the energy industry.

Aluminium Leader has been a strong promoter of the versatile use and positive impact of aluminium. In particular, we have written extensively about aluminium's close association with cutting edge technology.

From energy efficient airplanes and buses, to microprocessors and the latest smart phones, aluminium is often at the centre of revolutionary products. So, it should come as no surprise that we are once more reporting on how aluminium based technology is transforming the world albeit, not in the overtly "positive" way we have normally showcased the metal.

From energy efficient airplanes and buses, to microprocessors and the latest smart phones, aluminium is often at the centre of revolutionary products. So, it should come as no surprise that we are once more reporting on how aluminium based technology is transforming the world albeit, not in the overtly "positive" way we have normally showcased the metal.

Tesla Gigafactory by Tesla Motors

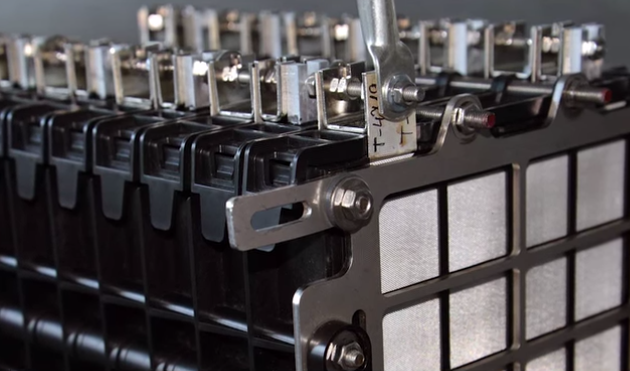

Aluminium air batteries have long been considered as a potentially revolutionary energy source. However, impediments to its commercial viability in the past have centred on the need to physically replace the aluminium nodes in batteries rather than electrically recharge them (a far more practical measure). However, Fuji claims to have addressed this by adding "strategically placed layers of ceramic and carbon", thereby suppressing the corrosion of the aluminium. The battery, they claim, can now be recharged multiple of times by simply adding water.

How Aluminium Air Battery Works?

Working principle of aluminum air battery by electrical4u.com

Aluminum air battery has air cathode which may be made of silver based catalyst and it helps to block CO2 to enter in the battery but it allows O2 to enter in the electrolyte, explains Electrical4u.com. Then this oxygen reacts with H2O in KOH electrolyte solution takes electrons from solution and creates OH- ions. These ions then associate with Al anode and create Al(OH)3 and release electrons. These electrons then flow to the air anode from aluminum cathode through the external circuit for compensating lack of electrons in the electrolyte solution due to cathode reduction reaction.

Aluminium air batteries could in theory have a capacity more than 40 times greater than lithium ion cells

As if this new tech breakthrough was not sufficiently bad news for Tesla, an Israeli based firm, Phinergy, is also pursuing a commercially viable aluminium air battery- and according to reports, has already made significant headway.

While we once again laud the impressive technologically achievements of aluminium based products, a part of us nonetheless empathizes with those industries that find it a little too hard to keep up. Hopefully Tesla will get onboard with the new aluminium air batteries sooner rather than later!

While we once again laud the impressive technologically achievements of aluminium based products, a part of us nonetheless empathizes with those industries that find it a little too hard to keep up. Hopefully Tesla will get onboard with the new aluminium air batteries sooner rather than later!