lifestyle

Shinola's Runwell Aluminium Turntable

The city of Detroit is world-famous for its industrial tradition but also its musical legacy.

16 January, 2017

One local company is bringing Detroit's manufacturing and musical roots together in its own way.

Shinola, the socially responsible startup in the American city of Detroit, has built its reputation on manufacturing quality goods while bringing jobs to the hard-hit city that's always relied on its "Rust Belt" automotive industry. Today, there are almost 400 people who work for Shinola in Detroit, making and selling watches – the company partners with Swiss watchmaker Ronda – as well as handbags and other leather goods, planners and journals. Now comes the company's first adventure in audio gear.

"There was a time when building watches in Detroit seemed like a crazy idea too," the Shinola team says on its dedicated audio website, which showcases its turntable operations. "As we introduce each new category we gain further traction in reaching our goal of creating more jobs."

"There was a time when building watches in Detroit seemed like a crazy idea too," the Shinola team says on its dedicated audio website, which showcases its turntable operations. "As we introduce each new category we gain further traction in reaching our goal of creating more jobs."

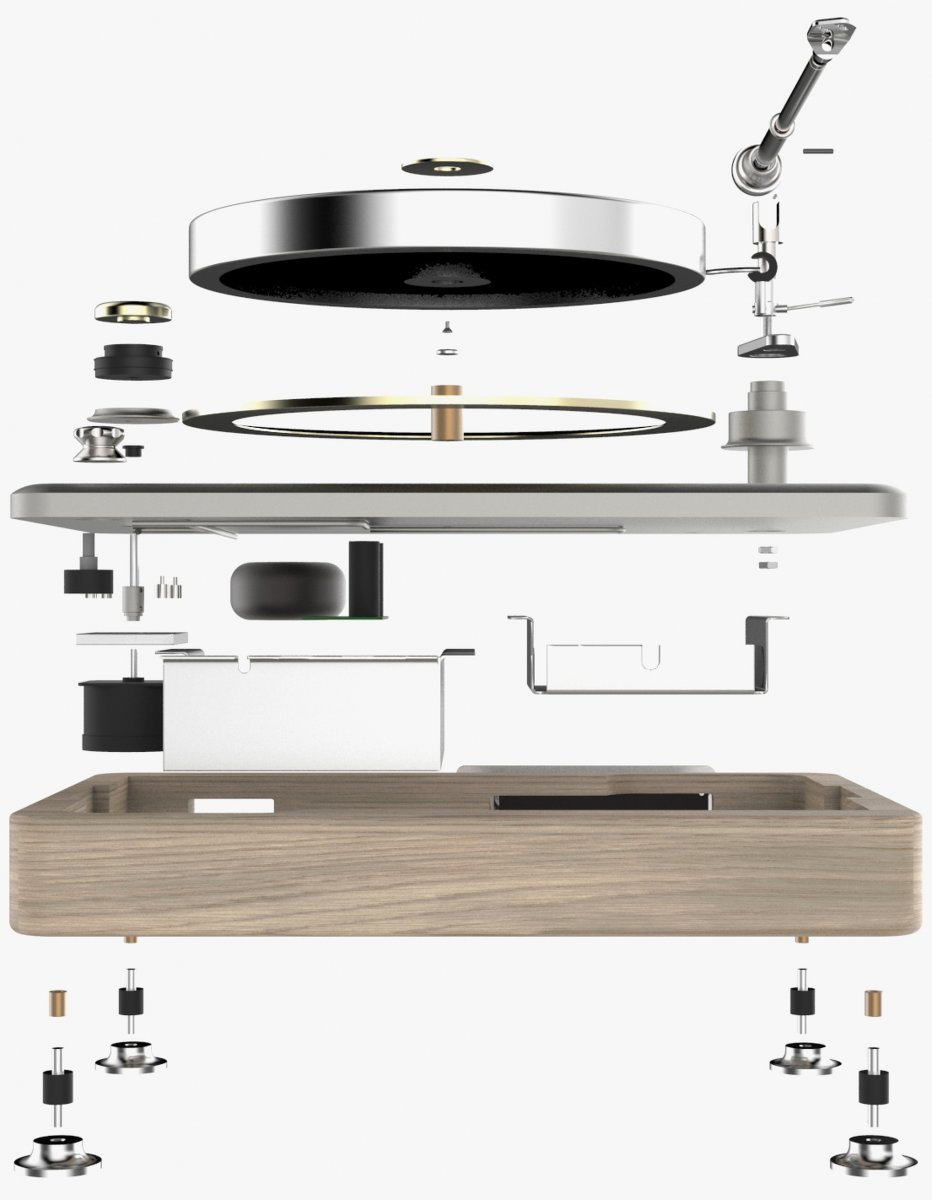

The Shinola Runwell Turntable is a $2,500 celebration of both the audio and ethos, available in a limited run of 500 units. The main plate, platter, and tone arm components are made with precision-machined aluminium, and assembled as "The Natural" in metal and wood, or as an all-black version.

The 40-pound Runwell is 19 inches wide and 14 inches deep, with a built-in phono preamplifier that makes it easy to connect to powered speakers or an amplifier. It operates with a belt-driven pulley that offers speeds at 33 1/3 or 45 rpm, accommodating both formats of increasingly popular traditional vinyl.

The 40-pound Runwell is 19 inches wide and 14 inches deep, with a built-in phono preamplifier that makes it easy to connect to powered speakers or an amplifier. It operates with a belt-driven pulley that offers speeds at 33 1/3 or 45 rpm, accommodating both formats of increasingly popular traditional vinyl.

Images: Shinola

Alex Rosson, the head of Shinola's audio products division, says the company always wanted to move into audio equipment manufacturing. Once he came on board with the expertise he acquired at Audeze, Shinola was ready to get its audio production up and running after a year of planning and design work.

"Our goal is to recreate what the artist intended," Rosson explains in a video of the machining process at New Jersey-based MDI, "And to do so, you need accuracy and precision." The platters of aluminium are precise down to the micron, and rely on levels of machining expertise used in NASA and laser optics.

"Our goal is to recreate what the artist intended," Rosson explains in a video of the machining process at New Jersey-based MDI, "And to do so, you need accuracy and precision." The platters of aluminium are precise down to the micron, and rely on levels of machining expertise used in NASA and laser optics.

Image: CNET

The aluminium block does more than look good, says Rosson. It absorbs vibration so that it doesn't affect the phono stylus cartridge, decreasing noise and contributing to the overall goal of delivering the highest quality of sound – quality levels that are just as meticulously detailed in the Runwell spec sheet.

At first, the turntables were built by hand in an old General Motors design facility that Shinola made its headquarters. Now, the public can watch the manufacturing process within the flagship Detroit store.

At first, the turntables were built by hand in an old General Motors design facility that Shinola made its headquarters. Now, the public can watch the manufacturing process within the flagship Detroit store.

The product's evolution was detailed in a recent Wired interview, which describes how one employee was building the turntables while teaching a team the best practices he's learned.

The initial goal, the company says, was to produce 40 Runwells per day, then 60, then 90. There are plans in the works for new additions to the audio equipment line, including headphones slated to be on the market next year.

Shinola's ambitious leap into audio gear is the product of a partnership with VPI Industries, a high-end American audio company that remains a family business after 35 years. Company co-founder Harry Weisfeld says that Shinola's vision in Detroit is a perfect match for his own commitment to creating American jobs and products that revive the manufacturing industry – and his own VPI line of gear relies heavily on aluminium to achieve its goals.

The initial goal, the company says, was to produce 40 Runwells per day, then 60, then 90. There are plans in the works for new additions to the audio equipment line, including headphones slated to be on the market next year.

Shinola's ambitious leap into audio gear is the product of a partnership with VPI Industries, a high-end American audio company that remains a family business after 35 years. Company co-founder Harry Weisfeld says that Shinola's vision in Detroit is a perfect match for his own commitment to creating American jobs and products that revive the manufacturing industry – and his own VPI line of gear relies heavily on aluminium to achieve its goals.

Image: Shinola

"We spent a lot of time on this," says Weisfeld. "This has taken way longer than we normally take. There's a lot of, "Let's get this exactly right.'"

Banner image: Shinola