TRANSPORT

Aluminium at the Heart of Formula One

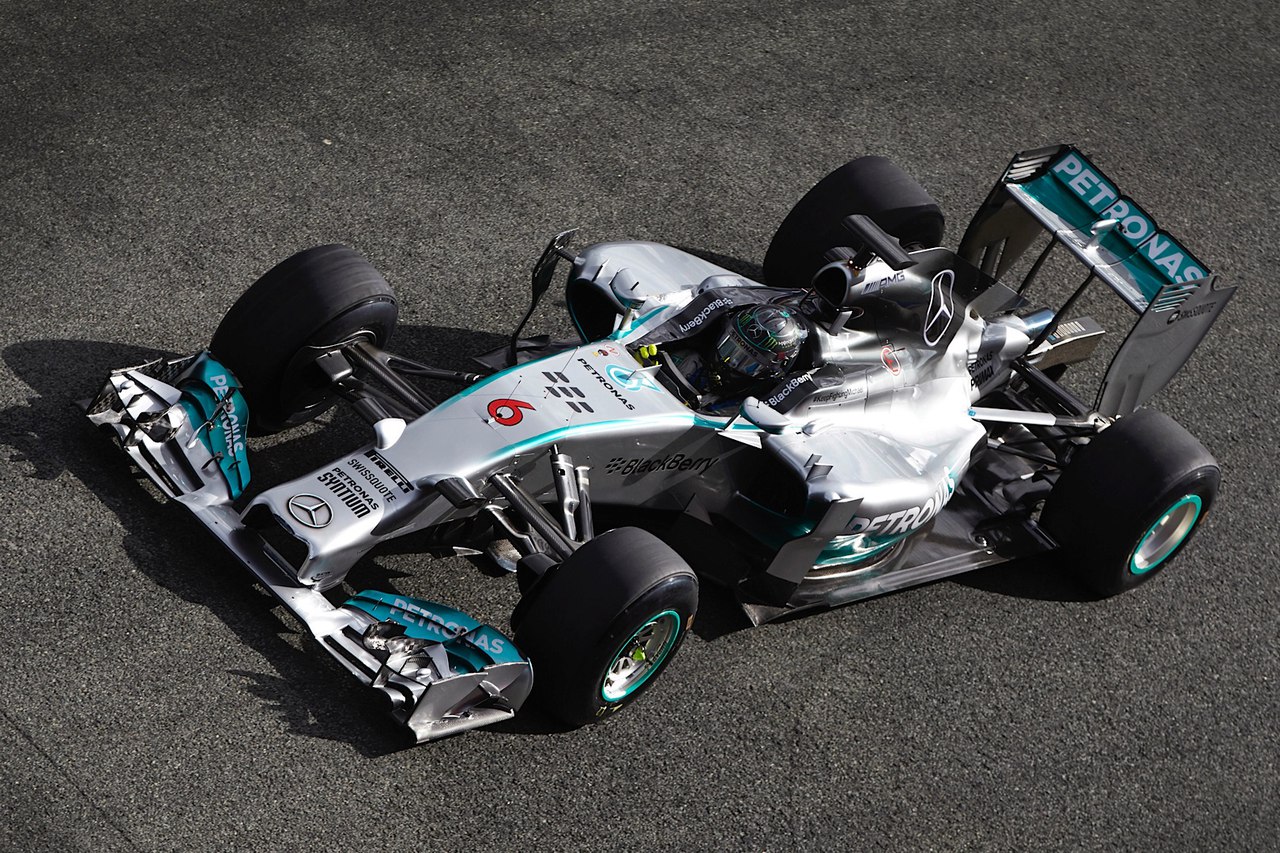

With Lewis Hamilton and Nico Rosberg sitting behind the wheel of their F1 W06 Hybrid, the Mercedes AMG Petronas team dominated the 2015 Formula One racing season

December 10, 2015

Whether it was the Mercedes W06 or Vettel's Ferrari SF15-T crossing the finish line, however, aluminium continued to play an integral part in creating Formula One's space-age cars.

Hamilton won his third world championship at the Circuit of the Americas in Austin, Texas in October, and Hamilton and Rosberg had already combined to win 12 of the 15 races before then (Ferrari's Sebastian Vettel took the other three).

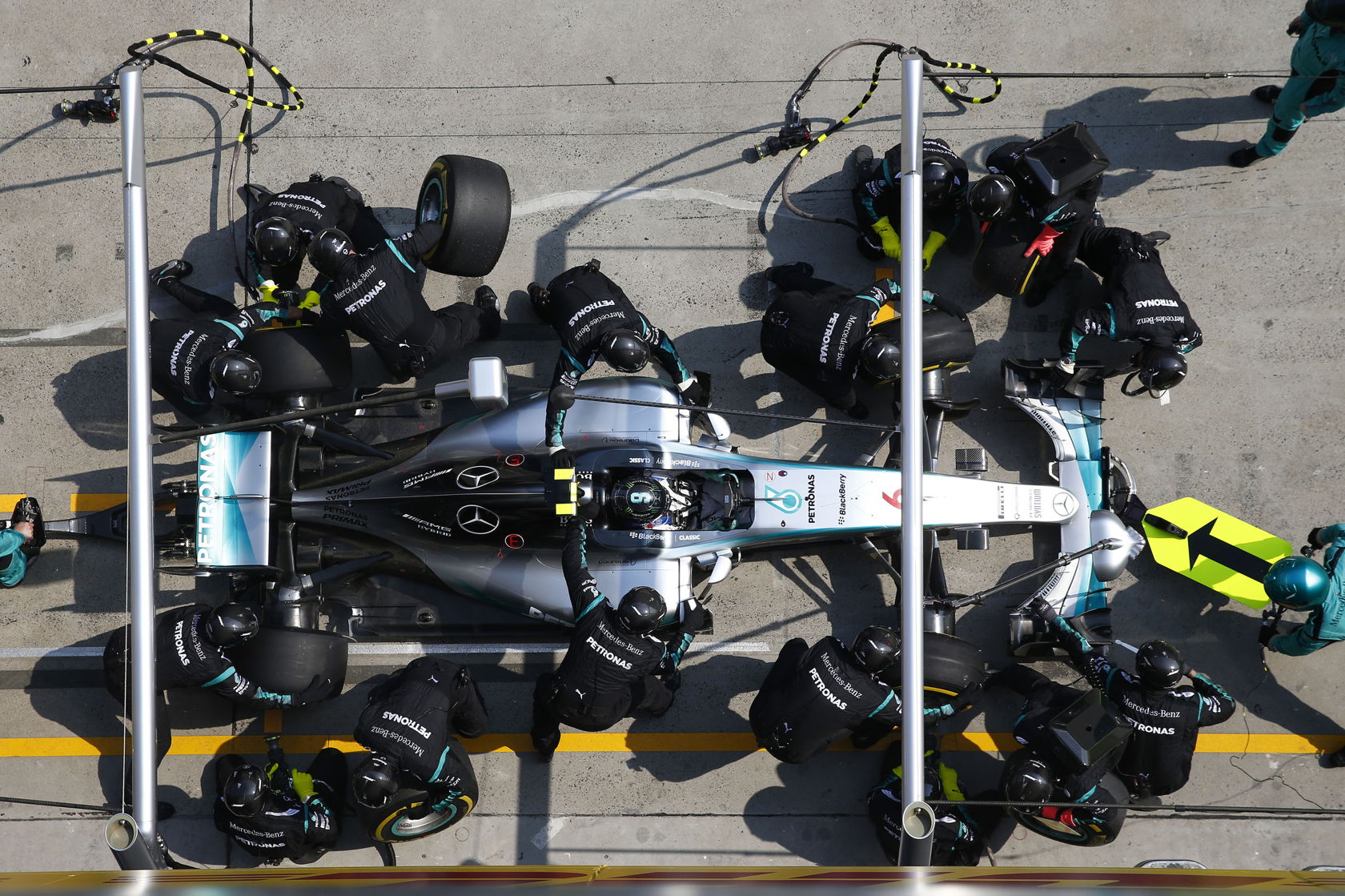

With only seconds separating first-place finishers and everyone else, F1 race teams invest millions of dollars and thousands of man-hours in making their cars as lightweight and aerodynamic as possible – all while ensuring the machines are tough enough to protect the drivers within.

With only seconds separating first-place finishers and everyone else, F1 race teams invest millions of dollars and thousands of man-hours in making their cars as lightweight and aerodynamic as possible – all while ensuring the machines are tough enough to protect the drivers within.

In the past, F1 chassis or monocoques (a French term which signifies "single shell" or load-bearing structural skin) were made out of aluminium. When Austria's Niki Landa won the 1975 World Championship, for example, his Ferrari 312T was made out of aluminium sheeting around a steel frame.

In 1980, however, McLaren technical director John Barnard introduced a carbon composite chassis for the first time. The rest of F1 laughed him off – and then quickly followed suit.

Instead of replacing aluminium with carbon fiber, racing teams since the 1980s have instead combined the two into the lightweight but durable chassis that Hamilton, Rosberg, and Vettel still rely on today.

In 1980, however, McLaren technical director John Barnard introduced a carbon composite chassis for the first time. The rest of F1 laughed him off – and then quickly followed suit.

Instead of replacing aluminium with carbon fiber, racing teams since the 1980s have instead combined the two into the lightweight but durable chassis that Hamilton, Rosberg, and Vettel still rely on today.

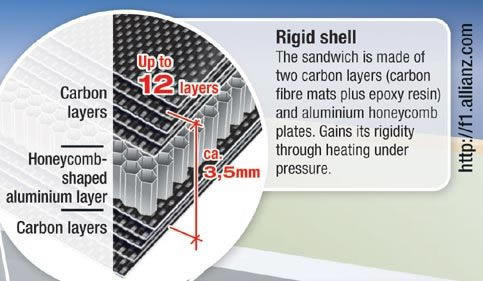

Modern F1 monocoques are a composite of an aluminium honeycomb

Modern F1 monocoques are actually a composite of aluminium honeycomb (between six and 15mm thick) covered by carbon "skins" on either side. Thanks to that honeycomb pattern, teams are able to keep chassis as light as 50 kg.

Alongside aluminium and carbon fiber, F1 engineers also rely on a wide range of other materials to help cars (and their drivers) weather the extreme conditions and potentially fatal hazards of high-speed racing.

According to Luca Marmorini, former head of the engine and electronics department at Ferrari Formula One: "We used more than 100 different alloys. Typically aluminium, titanium, copper, cobalt, tungsten are used. There is a standard to ensure quality and reliability, [and] that is the aerospace standard, but a lot of materials are developed with some suppliers and we can develop our own standards. Typically, if you have to mention a standard, it is aerospace standard."

According to Luca Marmorini, former head of the engine and electronics department at Ferrari Formula One: "We used more than 100 different alloys. Typically aluminium, titanium, copper, cobalt, tungsten are used. There is a standard to ensure quality and reliability, [and] that is the aerospace standard, but a lot of materials are developed with some suppliers and we can develop our own standards. Typically, if you have to mention a standard, it is aerospace standard."

With the Hybrid era still very much in its infancy, there is plenty of scope for innovation. The challenge at this stage is to find the key areas for performance gain based not just on what we have learned a year further down the line, but also where there is room for exploring new and innovative sources of competitive advantage

While all F1 cars are built out of similar materials and meet the same rigorous safety requirements, the most successful prove themselves to be a cut above. In analysing Lewis Hamilton's success in 2015, Sky News pointed to Mercedes' W06 as an essential factor in his title defence. The team behind Hamilton and Rosberg's racer, for their part, insist they will not rest on their laurels, even as their car outperforms the competition