While traditional batteries are closed systems, which dedicate most of their weight to their cathode, the metal-air batteries being developed by Phinergy draw in oxygen from outside the battery. This significantly reduces weight and offers greater capacity for providing energy.

By using aluminium plates (provided through a partnership with Alcoa) and generating a reaction with oxygen and water, Phinergy's battery releases electricity from the metal in order to power an electric car.

The company claims a single plate of (recyclable) aluminium can provide enough power for 32 km of driving. A 50-plate battery, by its calculations, can be used in conjunction with an existing lithium-ion battery to take a car over 1,000 miles.

One kilogram of aluminium can be used to release 4kWh of electricity and heat, and the Citroën C1 currently being used by Phinergy for demonstration purposes uses 25 kg of aluminium to generate 100kWh (equating to over 600 miles).

TRANSPORT

Aluminium-Air: The Future of Electric Cars

Popular electric cars like the Tesla Model S and the Nissan Leaf are increasingly providing consumers the opportunity to move away from fossil fuels and embrace a lower carbon footprint

December 8, 2015

These and other electric vehicles available today, however, still come with limitations that hinder their commercial appeal and leave many drivers hesitant to make the switch.

One of the core issues plaguing electric cars is mileage, particularly as existing lithium-ion batteries limit the range these vehicles can cover before needing to recharge. The Nissan Leaf, for example, has a listed range of 117 km, while Renault's newest Zoe promises 240 km.

Both are tough sells to European drivers who want to be able to travel over 400 km before they will consider an electric car.

In order to overcome the serious issue of "range anxiety" on the part of car buyers, Israeli startup Phinergy is promoting a method of supplementing lithium-ion batteries through the use of metal-air technology – aluminium-air technology, to be precise.

Both are tough sells to European drivers who want to be able to travel over 400 km before they will consider an electric car.

In order to overcome the serious issue of "range anxiety" on the part of car buyers, Israeli startup Phinergy is promoting a method of supplementing lithium-ion batteries through the use of metal-air technology – aluminium-air technology, to be precise.

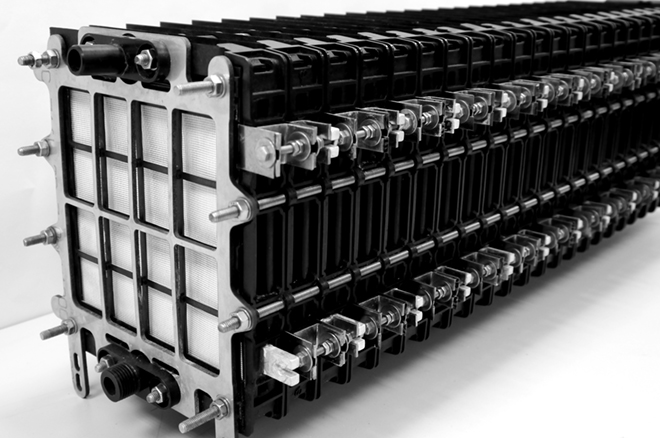

Phinergy battery train. Photo credit: Phinergy

Israeli Prime Minister Banjamin Netanyahu and US President Barack Obama meet with Phinegy CEO Aviv Tzidon. Photo by Charged Electric Vehicles Magazine

Phinergy's solution for maximizing the range of electric vehicles is attracting serious attention from major automakers as well as world leaders. In 2013, Phinergy announced talks with Renault-Nissan to produce a new electric car series as early as 2017. Even U.S. President Barack Obama has been impressed by the potential of the aluminium-air battery, meeting with Phinergy CEO Aviv Tzidon during a visit to Israel in March 2013 and asking Tzidon to reach out to American carmakers Ford and GM.

While Phinergy's system holds considerable promise for the future of electric vehicles, drivers already planning longer trips would need to keep a few points in mind. The aluminium-air batteries, in Phinergy's view, would serve as a "range extender" (as opposed to a constant replacement) that would need to be replaced once the aluminium was spent.

While Phinergy's system holds considerable promise for the future of electric vehicles, drivers already planning longer trips would need to keep a few points in mind. The aluminium-air batteries, in Phinergy's view, would serve as a "range extender" (as opposed to a constant replacement) that would need to be replaced once the aluminium was spent.

The air-diffuse cathode has Teflon on the outside, so it breathes air. From the inside, there is our nano-structure catalyst covering the aluminum on both sides. The reaction creates electricity while consuming aluminum.

Although aluminium-air batteries would not require traditional recharging, drivers would still need to add water to them after every couple hundred miles. Even with those caveats, however, aluminium-air has the potential to solve the overarching range issue with electric cars and allow drivers freedom from any guilt regarding emissions.